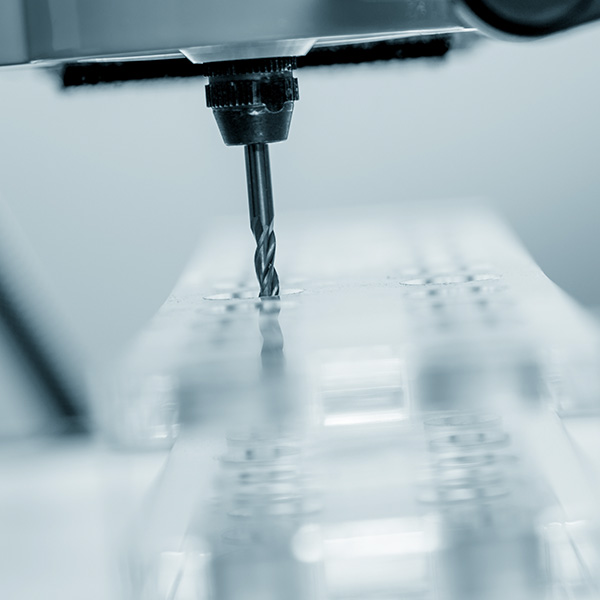

When you want to add excitement and interest to your POP displays, CNC routing is…

Laser Engraving and Laser Etching for POP Displays

Laser engraving and laser etching are terms used to describe two different effects that can be achieved on the materials of POP displays when using a laser on the material’s surface. Both types of effects are accomplished by applying a laser to remove material, typically by vaporization or melting, depending on the material.

The primary difference between laser engraving and laser etching is the depth of the material removal. Laser engraving is a deeper mark, while laser etching stays closer to the surface of the material. Thus, each type of laser marking creates a distinct look and is used to create different types of design effects.

When to Use Laser Engraving and Laser Etching

Both laser engraving and laser etching can be used to produce durable, high-contrast visual elements on POP displays, and they are often selected for intricate designs that cannot be accomplished with a CNC router, such as small lettering. These laser marking processes are also adept at repeatability, making them a popular choice among designers who require complexity and consistency in their design elements. For instance, both of these laser effects are frequently used by companies that wish to tightly control their brands and every aspect of their brand’s identity, such as the logo.

Selecting which of these effects to use on POP displays is often determined by the details of the design.

Benefits of Laser Engraving and Laser Etching

Laser engraving and laser etching are accurate and infinitely repeatable processes used to mark materials, either for design or for identification. The most common uses and benefits of these processes include:

Intricate patterns

Laser marking gives designers the freedom to create distinctive, detailed patterns that can set their POP displays apart and capture attention.

Variable height surfaces and dynamic scaling

Unlike painting a surface or applying a cling or decal, laser engraving and laser etching can be used to create variable-height surfaces and dynamic scaling for a unique visual and/or tactile experience.

Light control

The depth of laser marking on a surface has a direct impact on how the surface receives and reflects light, offering a broader pallet of design options to create more unique POP displays.

Design flexibility

Laser marking offers a wide variety of visual effects from surface etching to three-dimensional designs and reliefs. It can produce smooth curves and diagonals as well as sharp corners and crisp angles.

Consistency and repeatability

When consistency from one POP display to the next is a critical requirement, laser marking offers a highly repeatable design option that delivers.

Want to know more about laser engraving or laser etching for your next POP display project?

Let’s talk about your design.