In-house Services

Design, Prototype & Production

Merchandising Solutions offers a full range of services for all of your manufacturing needs, including design support, prototyping, and production of a variety of POP displays, signage, partitions, and OEM parts. All of our work is produced in our facility in Lancaster, Pennsylvania.

Our In-House Production and Specialty Capabilities

CNC Routing

We have CNC routers that allow us to cut complex shapes with precision. By using CNC machining, we are able to combine multiple processes into one setup, resulting in time and cost savings.

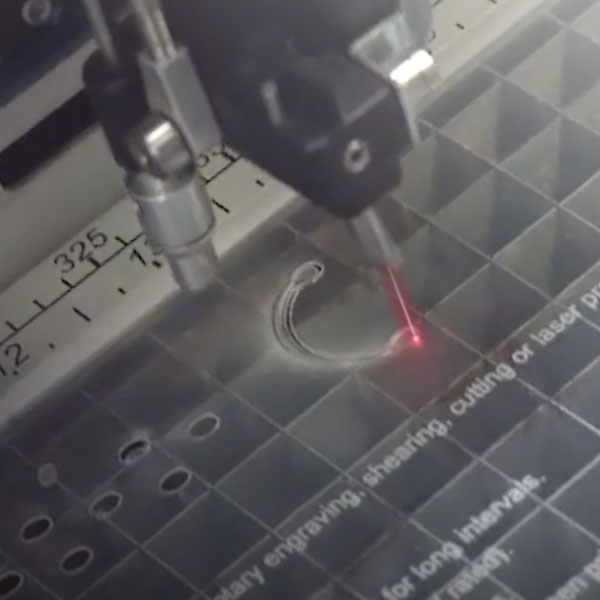

Laser Cutting

We can cut small acrylic parts such as letters for signs and logos. In addition, product holders that need square inside corners or that would be difficult to cut on the router can be cut on the laser.

Laser Engraving

Acrylic can be laser etched for decorative purposes or for edge lit LED signs that we make in house. We can also etch other materials that need permanent markings such as part numbers.

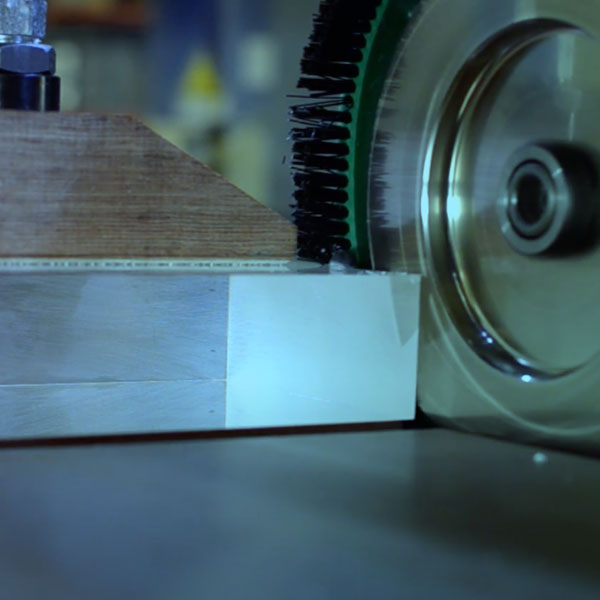

Edge Finishing

Our Bermaq® machine uses a diamond cutting head that creates a high quality frosted and polished edge on acrylics.

Polishing

Flame polishing is an economical way to create glossy edges on acrylic. For higher-end designs, we offer hand polished edges.

Line Bending

Straight line bends can be achieved with heat. The most common plastics that we bend are acrylic, polycarbonate, PETG and expanded PVC.

Assembly

We use various methods to assemble parts such as solvent welding, mechanical fasteners and interlocking parts. Whether you need a knockdown display or a more permanent fixture, we can build it.

Packaging

Products can be bulk packed as well as packed in specially designed individual cartons depending on your needs. We produce and ship from our Lancaster, PA warehouse.

Our Process

Before we begin, we first start by listening to you and reviewing your design or idea to get a detailed understanding of your specific requirements. Then, we help you develop your design. With our in-house prototyping capabilities, we can recommend design options and modifications for optimal manufacturability before moving to production. We then fabricate your POP display or product from your chosen material: high-quality plastics, wood, or metals. Once production is complete, your POP displays or products are distributed from our location or drop shipped if needed.

what we do: five steps

Our Materials

Merchandising Solutions draws upon a variety materials to create everything from stunning branded POP displays to precision equipment parts for OEMs. Our expert knowledge of materials means you get the best material for the look and manufacturing efficiency of your POP display or product.

- ABS

- Acrylic

- Expanded PVC

- HDPE

- Laminate

- Melamine

- Metal

- PETG

- Polycarbonate

- Polyethylene

- Polypropylene

- Styrene

- UHMW

- Wood

Ready to get started?

Let’s talk about your design. Give us a call or request a quote.