Laser engraving and laser etching are terms used to describe two different effects that can…

Five Quick Tips for Choosing a Manufacturer for Your POP Displays

To keep your next POP display project on time, on budget, and on point, we’ve put together five quick tips customers say they have found most valuable when building long-term relationships with dependable manufacturers of POP displays.

- Check that the manufacturer has experience with your type of application.

If you need a cosmetics display, for example, choose a manufacturer who has experience with POP displays for cosmetics. Evidence of previous experience signals that the manufacturer understands the unique expectations and demands placed on a cosmetics display, such as limited countertop space, ease of customer use, lighting features, and stocking and seasonal change-outs. - Work with a manufacturer who will help you control costs.

Controlling costs occurs at every stage of manufacturing POP displays, and a good manufacturer understands that. Display designers create beautiful designs to draw attention to a product, but they may not understand how to balance the aesthetics with the manufacturing process to get a project to stay within budget. An experienced manufacturer will work with you to help you control costs in the production side of the process and can guide you with decisions about material choice and other features that influence cost. - Look for material options and knowledge of materials.

To have the most design flexibility, choose a manufacturer who offers a reasonable selection of materials for POP displays that are relevant to the types of applications for which you’re designing. A common display material is acrylic, but designers also like to grab attention with other materials in POP displays, too, such as expanded PVC, metal, and wood. Selecting a manufacturer who offers a variety of materials will allow you to build a long-term relationship with a vendor you trust who can also give you the material options you want. Their knowledge of the materials will also help you when it comes to staying within your budget because they can guide your material choices to help you control costs. - Explore specialty capabilities.

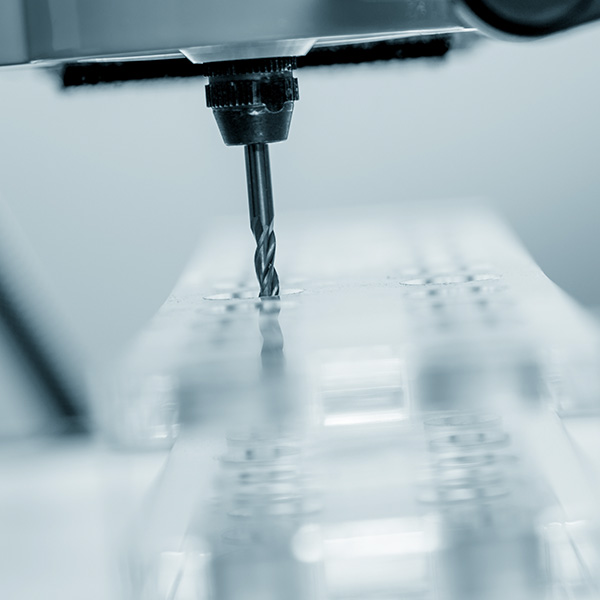

Just like having a variety of materials to choose from aids in expanding your design options, so too does having a number of capabilities. These can include services such as CNC routing, laser cutting, and laser etching as well as edge finishing and polishing. The more capabilities your manufacturer offers, the more options you have for your POP designs that you can produce with a single vendor. - Ask if the work is performed in house.

The last thing you want is a manufacturer who is outsourcing every detail of your project because every time your project is moved, it presents an opportunity for errors and increases the cost of your project. Whenever possible, choose a manufacturer who does all or most of the work in house. By reducing the number of hands touching your project, you’ll also significantly limit risks to your budget, your specifications, and your delivery schedule.

Need a quote for your next POP display project?

Let’s talk about your design.